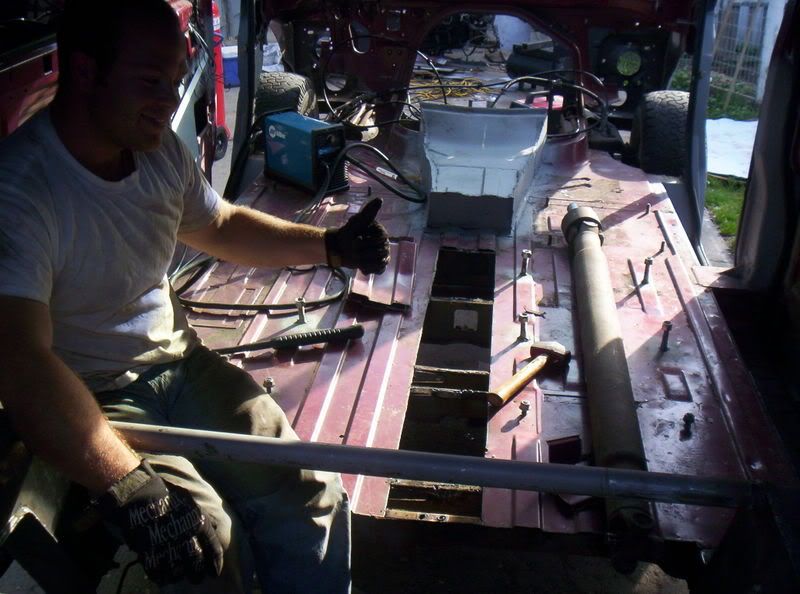

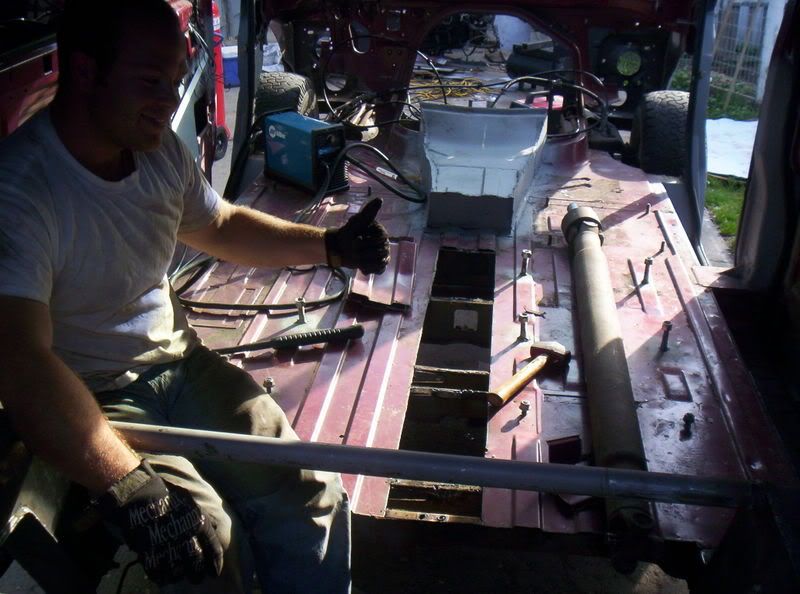

driveshaft tunnel pics

Posted: Sun Jun 10, 2007 6:56 pm

hey guys we fibished this the last few days,Im pleased with it even though I had trouble bending the pipe,but it looks good still and is strong

we mocked up where the drivesahft would sit,then cut out the sheetmetal where it would come through the floor when the van is layed out on those big wheels

then we welded steel plates to where we would make hoops with pipe,along the crossmembers of the vans floor,then made hoops with some 1 inch pipe and bent them in a pice of junk pipe bender I mistakenly bought

then my good buddy here cuts out the parts of the crossmembers that must be removed.You can see in the pics how the concept works.The front of the driveshaft will stay in one spot in the tranny and the rear will move up and down when the van is aired up and down .thus when the van is sitting on the ground the axle will come up on an extreme angle and come into what used to be the floor.One day we will cover up the works with sheetmetal and build a whole new floor most likely for that matter.I primed all of the tunnel and the notch you see in the rear today as well

we mocked up where the drivesahft would sit,then cut out the sheetmetal where it would come through the floor when the van is layed out on those big wheels

then we welded steel plates to where we would make hoops with pipe,along the crossmembers of the vans floor,then made hoops with some 1 inch pipe and bent them in a pice of junk pipe bender I mistakenly bought

then my good buddy here cuts out the parts of the crossmembers that must be removed.You can see in the pics how the concept works.The front of the driveshaft will stay in one spot in the tranny and the rear will move up and down when the van is aired up and down .thus when the van is sitting on the ground the axle will come up on an extreme angle and come into what used to be the floor.One day we will cover up the works with sheetmetal and build a whole new floor most likely for that matter.I primed all of the tunnel and the notch you see in the rear today as well